The New Energy Vehicle (NEV) primarily depends on makers of metal stampings. For new energy cars or, more particularly, electric vehicles, automotive metal stamping is a crucial manufacturing process that enables the production of many complicated components that adhere to stringent automotive criteria and rules.

Metal Stamping Applications

With accuracy, quality, and size being the most important criteria for components in various sectors, metal stamping technology is deemed essential to their growth. For example, consider some of the most important metal stampings used in producing new energy vehicles.

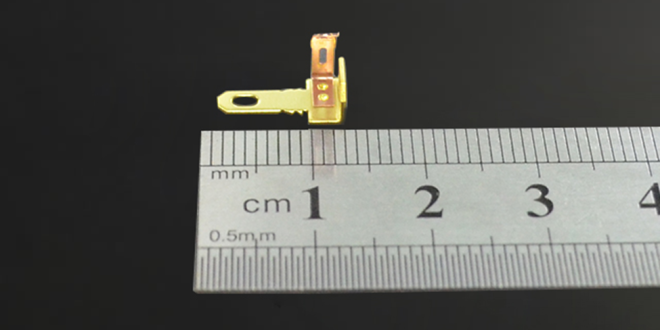

Charging Terminal Pile

Charge pile terminals are the necessary equipment for charging electric automobiles. The design of these EV charging heaps calls for several metal stamping components. Metal stamping may assist in shaping the exact components required for charging heaps.

Bayonet Equipment

The bayonet hardware is an electrical connection that assists electric car AC charging. It may be disassembled into various pieces, such as pins and nuts. Manufacturers create the proper shape and cut for your bayonet using metal stamping.

Transportation Terminals

Terminals for automotive connectors are used to create easy and speedy connections between one or more wires and headers. It helps link the many electric components inside a vehicle. Automotive metal stamping also contributes to the fabrication of these precision terminals.

Automobile Camera Gaskets

Seals and gaskets provide a close metallic connection between engine components. Miniaturized camera gaskets assist cover and sealing any apertures, including those where cables enter. Since they are intended to be as inconspicuous as possible, metal stamping is useful. Metal stamping facilitates the production of automotive camera gaskets in the correct dimensions.

Conclusion

When it comes to metal stamping, Hashimoto Precision is a market leader. Today, we can provide our customers with metal stamping parts and product manufacturing services at incredibly competitive rates. Moreover, we have the certifications necessary to be considered a reliable metal stamping manufacturer.

TECHGUIDANCES

TECHGUIDANCES